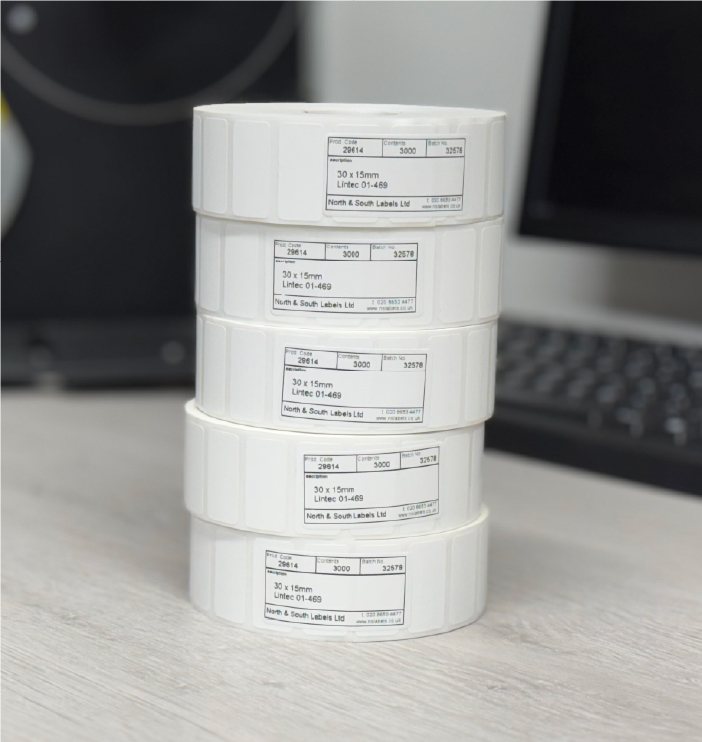

Direct Thermal Labels

Ribbonless printing for fast, cost-effective output in retail, logistics and warehousing.

Whether you’re labelling boxes in a busy warehouse, specimens in a cryogenic lab or PCBs through a solder-reflow oven, the right thermal-transfer combination delivers. If you’re comparing technologies, see our direct thermal labels for short- to medium-life applications.

Ready to start a conversation about your labels? Contact us to discuss your requirements, or read on to learn more about our thermal transfer labels.

Whether you need blank stock for maximum flexibility, colour-coded labels for process control, or a mix of fixed and variable artwork, our thermal transfer labels have you covered. Choose the style that best fits your workflow.

Plain White stock gives you total flexibility—ideal for printing barcodes, batch numbers and other variable data on demand. It’s the most economical option and delivers the highest contrast for scanners. If you're comparing print methods, you can also view our direct thermal labels.

Colour-Washed (sometimes called flood-coated) labels feature a solid colour background—often used in industrial settings to denote days of manufacture, production processes, or shipping destinations. These are also available through our custom label manufacturing service.

Part-Printed labels strike the ideal balance—your logo, safety icons, or regulatory art are pre-printed at the factory, and you still have blank zones for variable data such as barcodes or expiry dates. Ideal for consistent branding and widely used across our custom pre-printing options.

Our standard substrates—paper, polypropylene (PP) and polyester (PET)—cover the vast majority of label applications, offering economical, high-contrast printing for everyday needs. If you’re comparing print technologies, see our direct thermal labels for short- to medium-life applications.

Standard Substrates:

Speciality Substrates:

For environments that push labels to their limits, our speciality materials are engineered for extremes—temperature, chemicals and security—including:

Contact us to help select the ideal material construction—face stock, adhesive and liner—for your specific needs.

Choosing the right adhesive is crucial for reliable performance. We offer a variety of options to ensure your labels stay put in any environment.

Adhesive Options:

Not sure which adhesive is best? Our team can guide you.

Choosing the right adhesive is crucial for reliable performance. We offer a variety of options to ensure your labels stay put in any environment, with specialist constructions available through our custom label manufacturing service.

Adhesive Options:

If you're still exploring formats or core sizes, our thermal label size guide can help ensure full compatibility with your printers and application. Not sure which adhesive is best? Our team can guide you.

A: Direct thermal prints without a ribbon and is best for short-life labels. Thermal transfer uses a ribbon to create more durable prints on paper and films—ideal when you need longevity, chemical resistance or extreme temperature performance.

A: Use wax on paper for cost-effective everyday barcodes; wax/resin for tougher paper or synthetics; and resin on polyester or polyimide for maximum resistance to abrasion, chemicals and heat. Always match the ribbon to the face material for best results.

A: Paper, polypropylene (PP) and polyester (PET) cover most applications. For specialist needs, we also offer cryogenic-grade films and high-temperature options.

A: Paper with a freezer-grade adhesive is the go-to for storage down to −80 °C — reliable and economical. For extra tear or moisture resistance, we can pair polypropylene or other films with freezer adhesives.

A: A cryogenic-grade polyester face with a compatible cryo adhesive is ideal for liquid nitrogen or vapour-phase storage. Pair with a resin ribbon for maximum print permanence.

A: Polyimide (commonly used on PCBs) with a suitable resin ribbon withstands solder-reflow and other high-temperature processes up to about 260 °C.

A: Yes — plain white for on-demand data; colour-washed (flood-coated) for colour-coding; and part-printed with logos or marks while leaving space for variable data.

A: Permanent, removable and freezer-grade (to −80 °C) as standard, plus specials for low-surface-energy plastics, rough surfaces, medical and repositionable uses.

A: Yes — we supply common roll/core sizes and orientations for leading thermal transfer printers such as Zebra, TSC, SATO and Citizen. Tell us your model, core size and wound direction — we’ll match the spec.

Still have questions? Contact us for tailored advice or samples.